PREFABRICATION METHODS

Our practice, while fundamentally concerned with issues of space, light, and texture, is underpinned by an exploration of “how to build.” Construction technology is hundreds of years old, and while other industries have rapidly adopted new fabrication technologies, the fields of architecture and construction have been averse to exploring similar possibilities. In our own small rebellion, we have explored modular prefabrication through shipping containers and wood-frame boxes, panelized prefabrication with Structural Insulated Panels and German Eco-panels, and are currently reviewing opportunities to utilize cross laminated timber panels in multi-story construction. Our explorations have materialized into actual built works rather than mere theoretical musings, and with the variety of lessons learned, we continue to research the opportunities inherent in new construction technology.

MODULAR

Part of our research at Tomecek Studio is to better understand and question how we construct projects. We believe that prefabrication can be a great choice for the right project. The degree of prefabrication and the manufacturing facility that we choose varies greatly with both client and project goals. At Tomecek Studio, we are always looking for ways to utilize the newest construction techniques. Ultimately, to be effective, the options with these new techniques must parallel project goals. While quality space that fits our clients needs is our ultimate desire, architectural design, fabrication and client intentions dictate how the project begins to materialize. Our experience has found that when prefabrication, as a project delivery method, aligns with these goals, we can create a project tailor fit for our clients that may indeed save both time and money.

CONTAINERS

In our climate, insulation is a major issue and the modification of containers requires much more involvement from the steel trades. These projects tend to be smaller, which often results in higher cost in dollars per square foot. Misinformation exists about the ease of container construction. In reality, the container acts as only a single component of the project, and depending on the modification, you are still building with a traditional timeline given the sub-trades that need to run through the project. It should be noted that TSA is custom architectural practice with unique clients and sites. Cost savings may be found with a pre-designed container product or model. Other factors to consider are methods of insulation and steel fabrication costs which tend to drive costs higher

PANELIZATION

Our studio’s early experience with Structural Insulated Panel Systems (SIPS) demonstrated a holistic understanding of structure and insulation. These panelization systems have the ability to thoroughly insulate while minimizing thermal breaks over distances up to 20’. We learned that well sealed buildings are the key to energy efficiency. This research took us to Germany to examine a high quality, smart eco-panel system. The German approach includes sustainably resourced materials with quick connect systems. Our LEED Platinum certified Alpine project was delivery and erected in 10 days.

INSULATED CONCRETE FORMS (ICFs)

Insulated Concrete Forms (ICFs) are interlocking blocks made of styrofoam. The inner core is a void with plastic ties that provide separation. Once assembled on site, the void is filled with concrete, and the styrofoam formwork becomes a highly insulating layer. This system takes advantage of both structural and insulation superiority while providing additional benefits including acoustic separation. Our Telluride project utilizes ICF walls and floors with a Structural Insulated Panel (SIP) roof. There are many variations on this approach, including Quadlock .

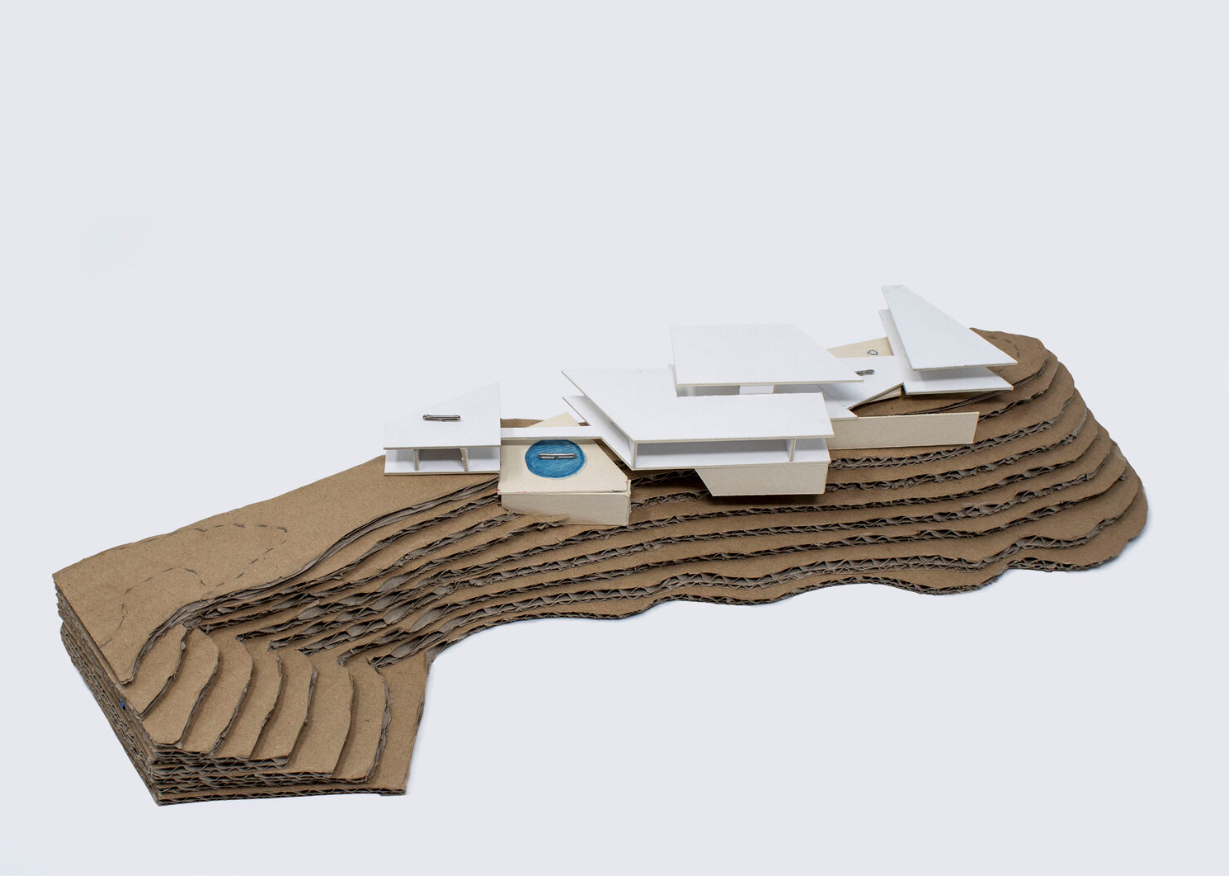

BOLTED MOMENT FRAMES

Bolted Moment Frames leverage mostly cold-formed, high-tensile strength, light gauge galvanized steel. This sustainable material is cut to tolerances of 1/8th of an inch and pre-drilled for rapid on-site assembly. Additionally, the steel is galvanized with a G-60 or G-90 rating, ensuring it is resistant to rust and corrosion. Compared to traditional wood construction, steel does not warp nor bloat, and it is an engineered material with precisely known and calculated load-bearing capacities. As a result, a steel structure can be designed more accurately and with less waste than a traditional structure.

We excel at working with unique and challenging sites. When building close to the top of a ridge or other geological challenging area, we look for ways to minimize foundation costs which includes excavation and sometimes expensive blasting. Our Hill Station project is meant to touch the ground lightly on drilled piers - the Blue Sky Building System is a perfect fit for durability.

QUONSET HUT

Quonset Hut construction was first utilized by the US Navy for quick and easy erection. The corrugated curved ribs provide their own structural stability when bolted together. Driving across the Midwest, one can see versions of these metal shells scattered across agrarian farmlands, usually storing equipment and supplies. The Quonset Hut does a very efficient job of covering a large amount of area with minimal material effort. Architecturally, we were called upon to incorporate this 40’ wide, 20’ tall thin overhead shell into a lakeside retreat.